I have been writing recently about the benefits of Risk-Based Gas Mapping, but of course the Geographic approach has its advantages too: the analysis is cheaper, quicker, well-supported in industry, and has an appropriate level of detail for small or low-risk projects. Choosing the right method for your project can be challenging, especially as in:Flux has made risk-based methods more cost-effective.

Here are some broad-brush guidelines from my own experience with the two methods.

Use Risk-Based Mapping…

- On large projects that have significant risk associated with explosion or toxic gas transport. For these projects, modeling gas leaks to a higher standard using CFD is appropriate.

- For any project that involves significant toxic gas hazards, such as H2S. The benefits of risk-based gas mapping over geographic are particularly pronounced for toxic gas detection.

- Where a reduction in detector count results in significant cost savings.

Use Geographic Gas Mapping…

- When the project performance standard specifies it. Always defer to the governing documents and methodologies required for the project.

- On small, low-risk projects.

- For low-risk modules that are part of a larger project.

A combination of Risk-Based and Geographic Gas Mapping often makes sense. In that case, risk-based is best used on the high-risk areas, while geographic can be used on the other modules in the project.

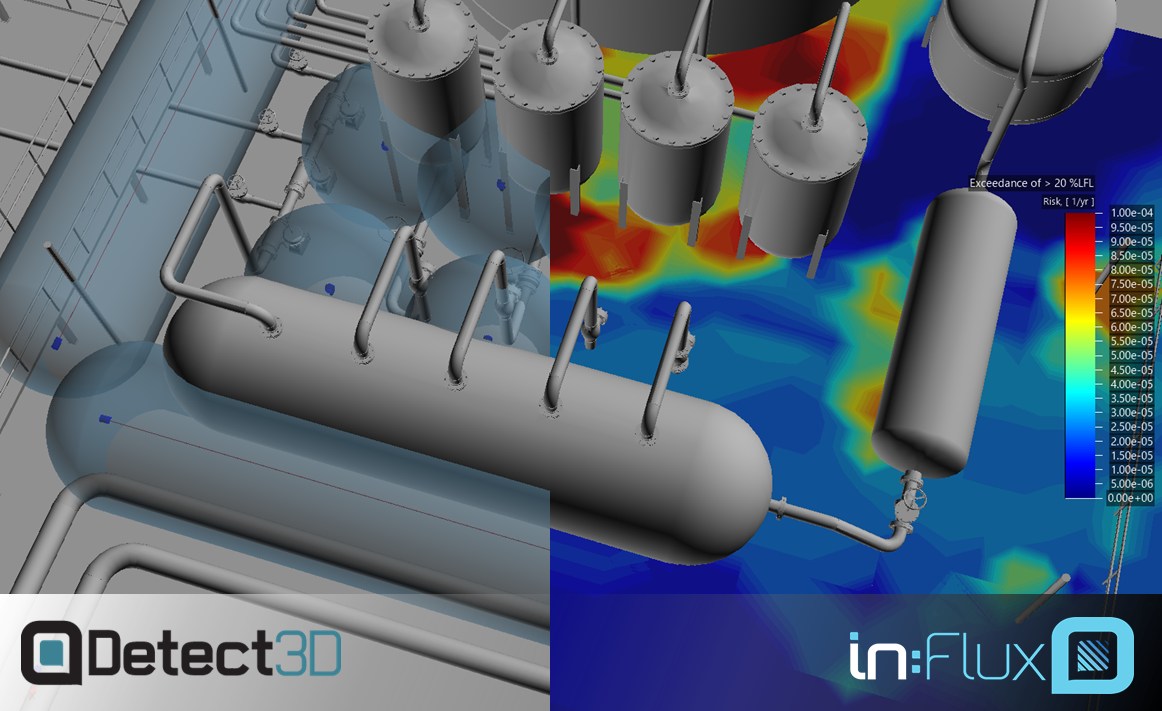

As Detect3D and in:Flux can interface with each other, it is also possible to run both geographic and risk-based methods on the same module. Doing this provides valuable insight into the strengths and weaknesses of each layout, to support decisions regarding the gas detector layout.

Find us